Customized Smart Automotive Door Systems

From design to mass production, RUIYYCO delivers tailored soft-close and power sliding door solutions with high compatibility and reliability.

We provide a one-stop customization service covering the entire process from concept to production.

Whether it’s a soft-close door, power sliding door, automatic door system, or exclusive component, RUIYYCO designs and manufactures solutions with exceptional compatibility, reliability, and automotive-grade quality.

In the smart door system field, every customized solution strikes the perfect balance between

functionality, safety, and comfort.

Customization Process

RUIYYCO offers a 10-step customization process from requirement communication to mass production and delivery—efficient, transparent, and fully traceable.

Design and Production

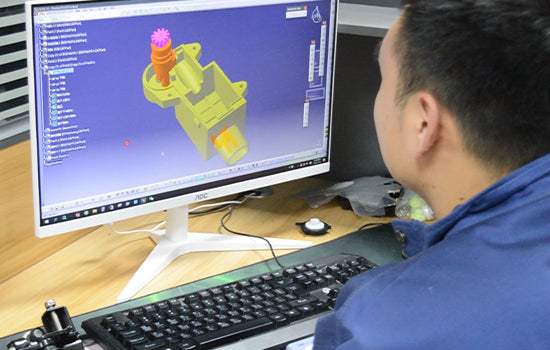

RUIYYCO R&D and Design Capabilities

RUIYYCO has a professional R&D team of over 30 engineers, with key

members from leading international suppliers such as Kiekert and Magna,

bringing more than 20 years of experience in automotive door locks and

intelligent door systems.

1. Multi-domain Expertise:

Automotive electronics, mechatronic control, structural design, and mold

development.

2. 70+ Vehicle Data References:

Precise development based on original vehicle data.

3. 50+ Technical Patents:

Covering soft-close locks, sliding door drives, and motor control systems.

4. Automotive-grade Testing Standards:

Waterproof, dustproof, durability, and extreme condition validation.

Prototype Development

Rapid Iteration, Precisely Replicating Mass-Production Conditions

RUIYYCO rapidly develops and validates prototypes based on confirmed

technical solutions and vehicle data, accurately simulating mass-production

conditions. Supports A/B/C sample stages with 3D/2D drawings, wiring

diagrams, and installation guides. Using CNC machining, 3D printing, and

rapid tooling, we ensure fast delivery, with remote or on-site engineering

support—typically completing 1–3 prototype sets within the scheduled

timeframe.

Product Testing

Automotive-Grade ValidationReliable Performance

RUIYYCO conducts vehicle-grade testing across four key dimensions—

functionality, durability, environmental resistance, and system compatibility

—to ensure reliable performance under extreme conditions. Tests include

compatibility with key control, central lock, and child lock systems;

100,000-cycle life tests on lock bodies, drives, and rails; IP67-level

waterproofing, corrosion, and thermal shock tests; plus vibration, noise,

and mechanical strength assessments. Each product undergoes real-

vehicle validation across multiple road conditions, with complete reports

and improvement recommendations provided.

Mass Production Capability

Scalable Production Stable Delivery

RUIYYCO, operating under the IATF16949 and ISO9001 quality

management systems, achieves efficient and stable mass production

through automated assembly and full-process quality control.Key

processes include in-house mold development, automated screw fastening,

rail and motor assembly, combined with online monitoring and 100%

functional testing for complete batch and serial number traceability.

Supported by a qualified supplier system, inventory management, and

global logistics network, RUIYYCO ensures rapid and reliable delivery.

The annual production capacity reaches approximately 120,000 sets of

soft-close door systems and 130,000 sets of power sliding doors (subject

to actual production scheduling).

Training & Technical Support

Delivery Is Just the Beginning

RUIYYCO offers end-to-end training and technical support covering

installation, commissioning, maintenance, and after-sales, enabling

partners to quickly operate and maintain stability. Services include

installation guidance, torque and wiring standards, control unit setup and

function linkage, manuals, wiring diagrams, instructional videos,

troubleshooting checklists, remote or on-site engineer support, warranty

and spare parts supply, as well as sales and technical training with

certification.